(08/02/2025)

Background:

Innovation often emerges from necessity, and this was precisely the case with a slip ball retrofit system I developed for an MD82 full flight simulator. The challenge at hand was well-known: the original brass tube system had a tendency to pinch the cables, making it difficult to “unpinch” without replacing the entire brass tube sections and rendering the instrument unreliable over time. Even with careful handling, this issue persisted, leading to the need for a long-term, sustainable solution.

The constraint was clear: whatever replacement was designed had to fit within the narrow 2.5mm gap between the HSI and ADI while maintaining full functionality. The project required not just mechanical ingenuity but also an elegant electronic solution. At its core, the system involved a PCB designed to convert the -10V to +10V reference into a 0V – 5V signal for an ATmega MCU, ensuring seamless integration into the existing flight simulator architecture.

Skills Involved:

CAD Design (Solidworks)

Electronic circuit design, schematic and simulation

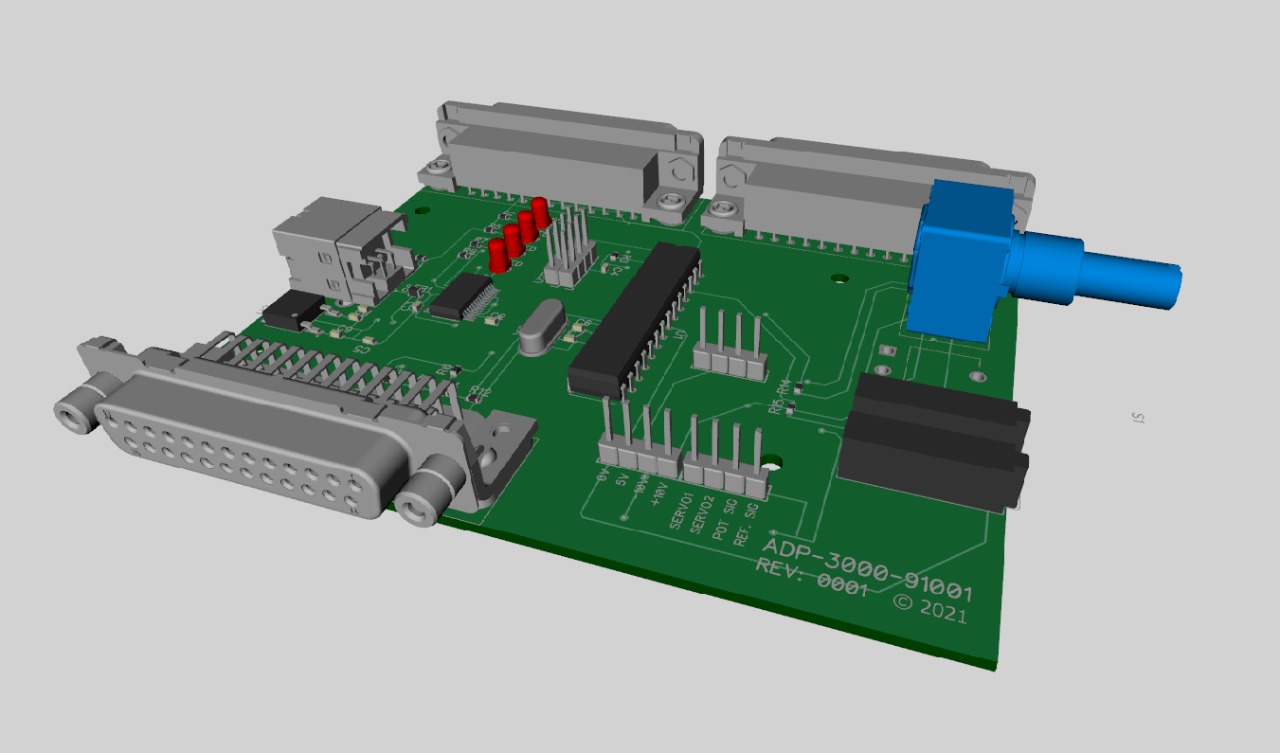

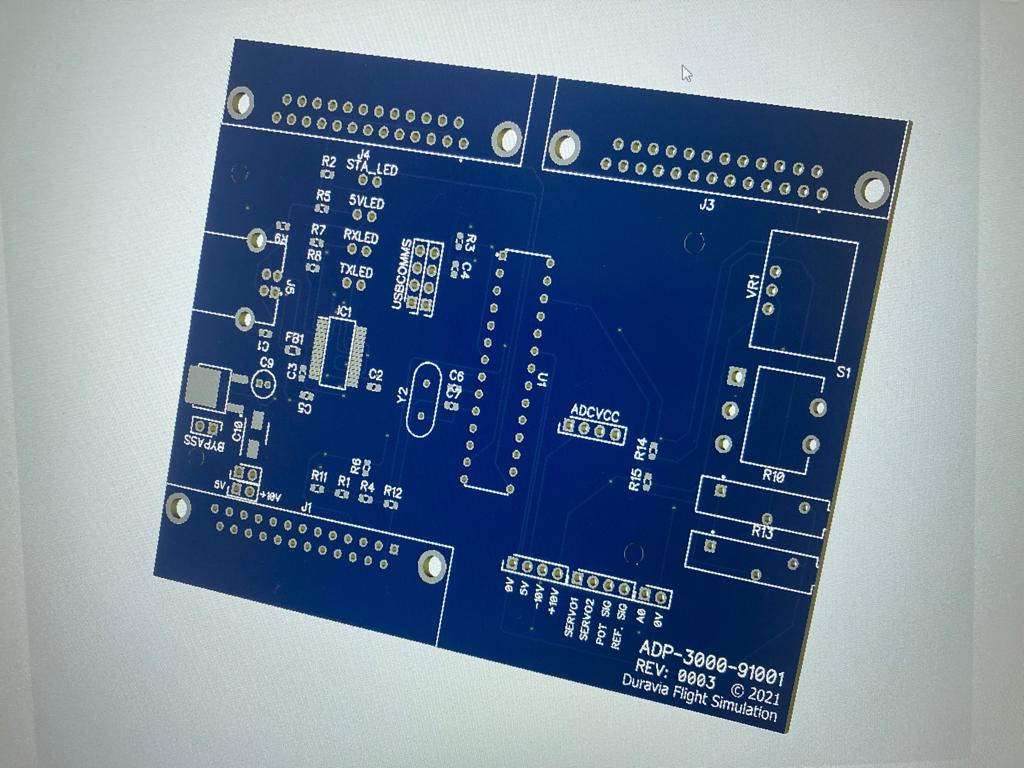

PCB Design: 2D tracking and 3D visualisation

Electromechanical Integration

C++ Firmware development

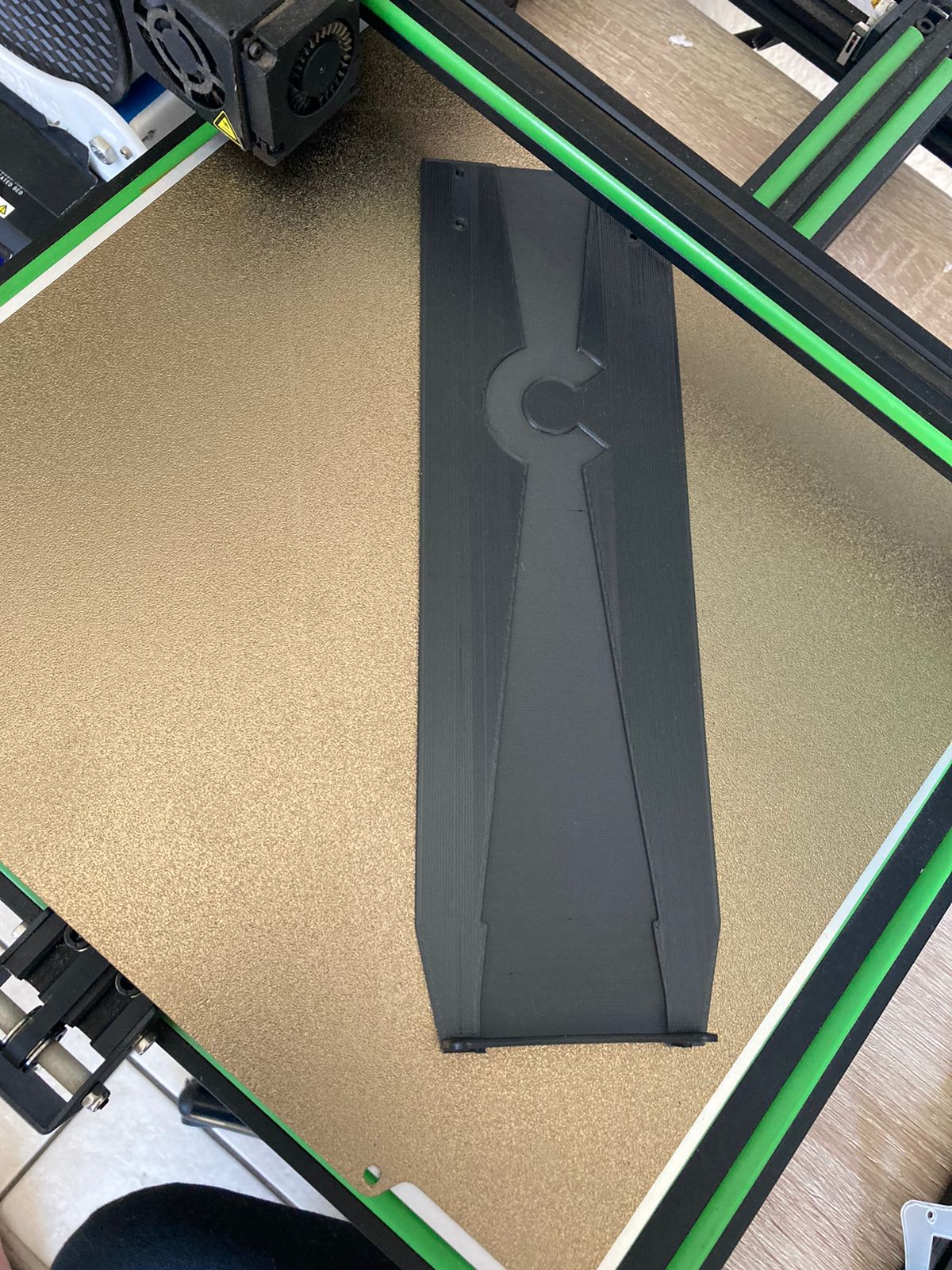

CAM

Physical prototype and production prototype assembly

Some patience…

(08/02/2025)

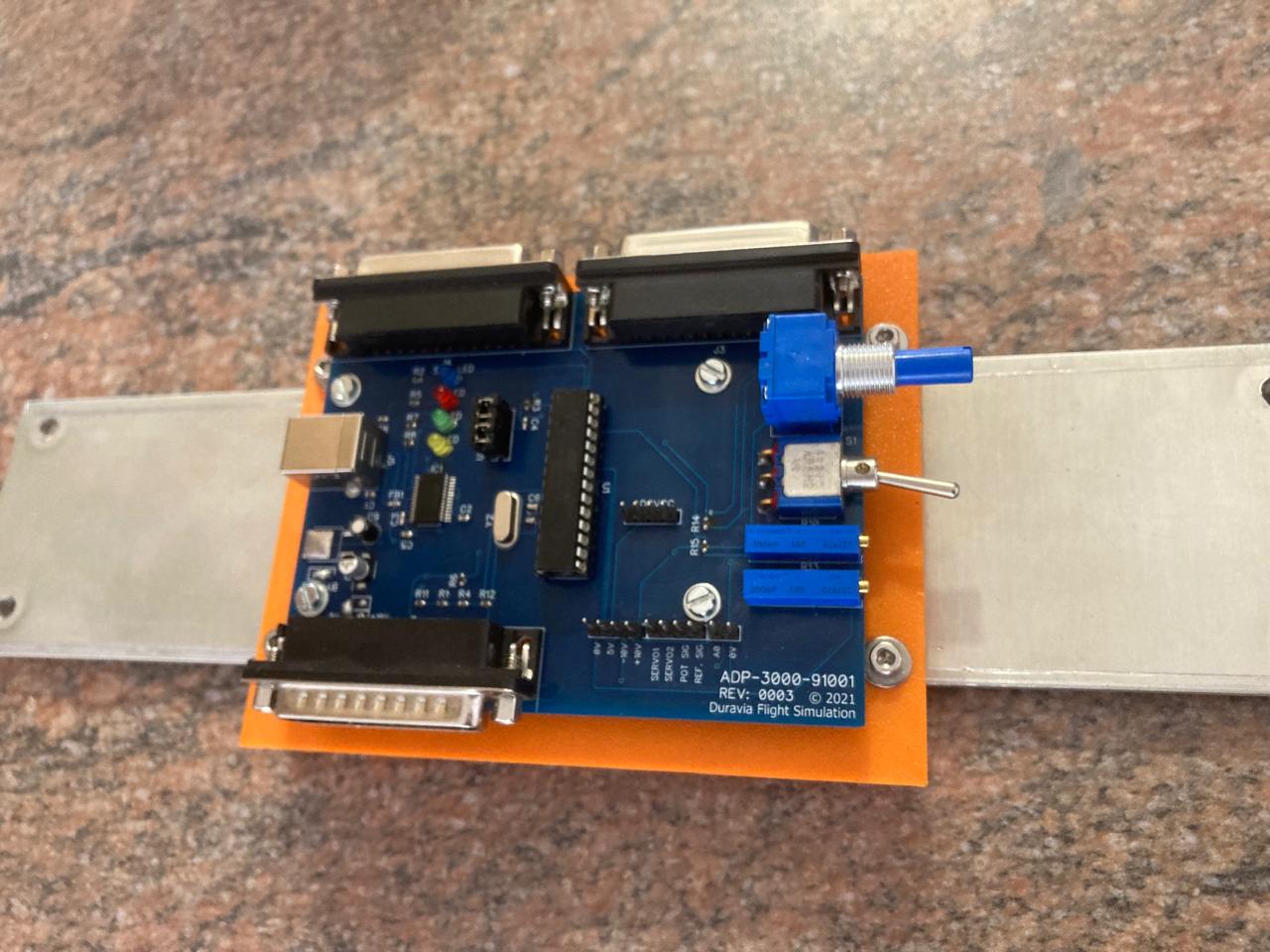

Added a photo of the end result on the PCB for the Slipball controller with mounting brackets that slide onto an aluminium plate in the Rediffusion simulators IO cabinet.

(24/09/2023)

More details on this little project to follow…

Leave a Reply